-

- Coaxial Adaptors

- Diffusers

- Drop Tubes

- Dry Disconnect Caps & Adaptors

- Extractor Pipe Caps

- Fill Caps Locking

- Fill Caps Vented

- Fill Caps Watertight

- Fill Pipe Extensions

- Relief Cap & Arresters

- Side Seal Caps & Adaptors

- Swivel Adaptors

- Tank Monitor Caps & Adaptors

- Test Well Caps & Adaptors

- Tight Fill

- Top Seal Caps & Adaptors

- Vapor Recovery Caps & Adaptors

-

-

-

- Adjustable Level Sensor with Alarm

- Alarms

- Clock Gauges

- Clock Gauge Alarms

- Dual Point Clock Gauge

- Electronic Gauging Systems

- Gauging Alarm & Sensor Accessories

- Gauging Tapes

- Indicator Paste

- Interstitial Sensors & Indicators

- Liquid Level Tank Gauge

- Mechanical Gauges (Numerical Readout)

- Sensors and Probes

- System Interface

- Test Measure Cans

- Thermometers

- Vent Alarms

-

-

-

-

-

- Ag Tank Emergency Valves

- Air Shut-Off Valves

- Anti-Siphon Valves

- Back Pressure Valves

- Ball Valves

- Barrel Faucets

- Bushings

- Check Valves

- Companion Flanges

- Emergency Valves

- Expansion Relief Valves

- Extractor

- Faucets

- Foot Valves and Suction Stubs

- Frost Proof Drain Valve

- Gate Valves

- Offsets

- Oil & Molasses Valves

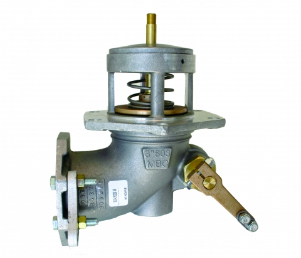

- Overfill Prevention Valves

- Quick Couplings

- Solenoid Valves

- Union Check Valves

- Wafer Check Valves

- Water Drain Valves

-

CARB Installer Certification

We've made CARB Installer Certification quick and simple. You will be provided with the tools needed to complete your certification requirements online. There is no cost to register and complete this exam.

Carb Certification-

Our Storied Past

-

Job Openings

- Full-time General Laborer/Powder Coat, 1st Shift

- Supervisor, 2nd Shift

- Millworker

- Sales Account Manager

-

Our Capabilities

State-of-the-art rapid prototyping, research and development. We specialize in small and medium runs of brass and aluminum alloys with complete in-house CNC machining and finishing capabilities.

Capabilities